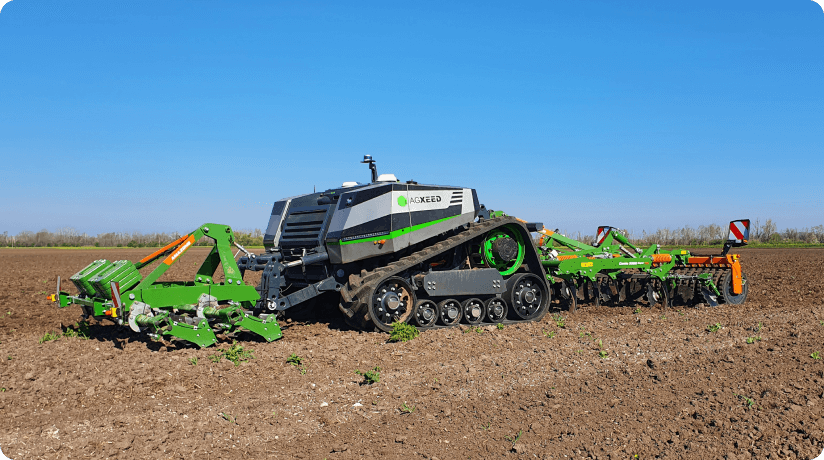

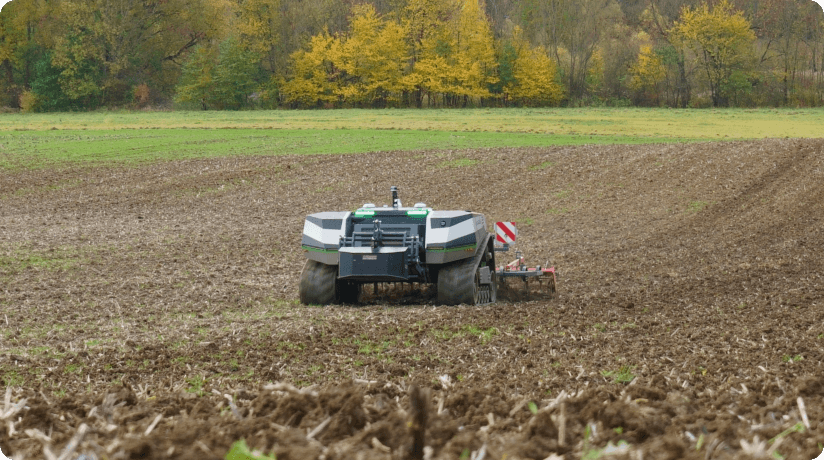

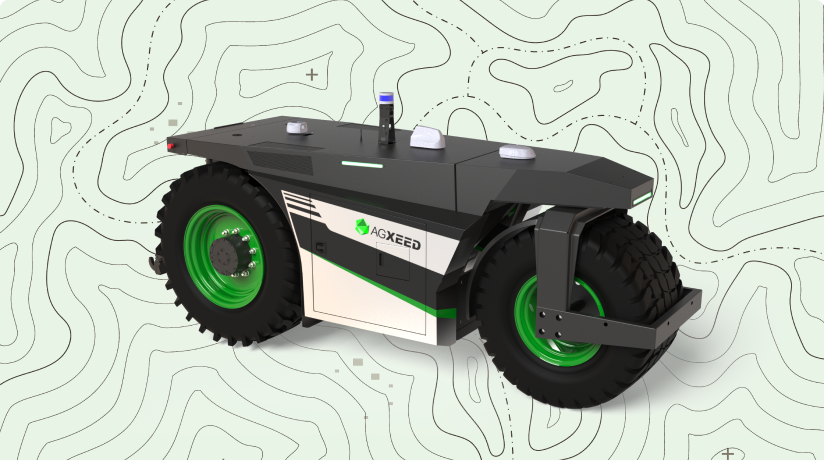

AgBot 5.115T2

Ready for hours of high-capacity work on broad arable land

Soil preserving crawler tracks

Adjustable track width from 1.90 m up to 3.20 m

Technological AgXcellence

Standard

control valves

Safety

mechanisms

LiDAR

detection

front and rear

Cameras

Standardized

3-point linkage

App

control

Data-

gathering

standard

ISOBUS / TIM

Safety measures

- Geofence system

- Visual indicator lights

- Audible warning alarm

- Emergency stop buttons around the machine

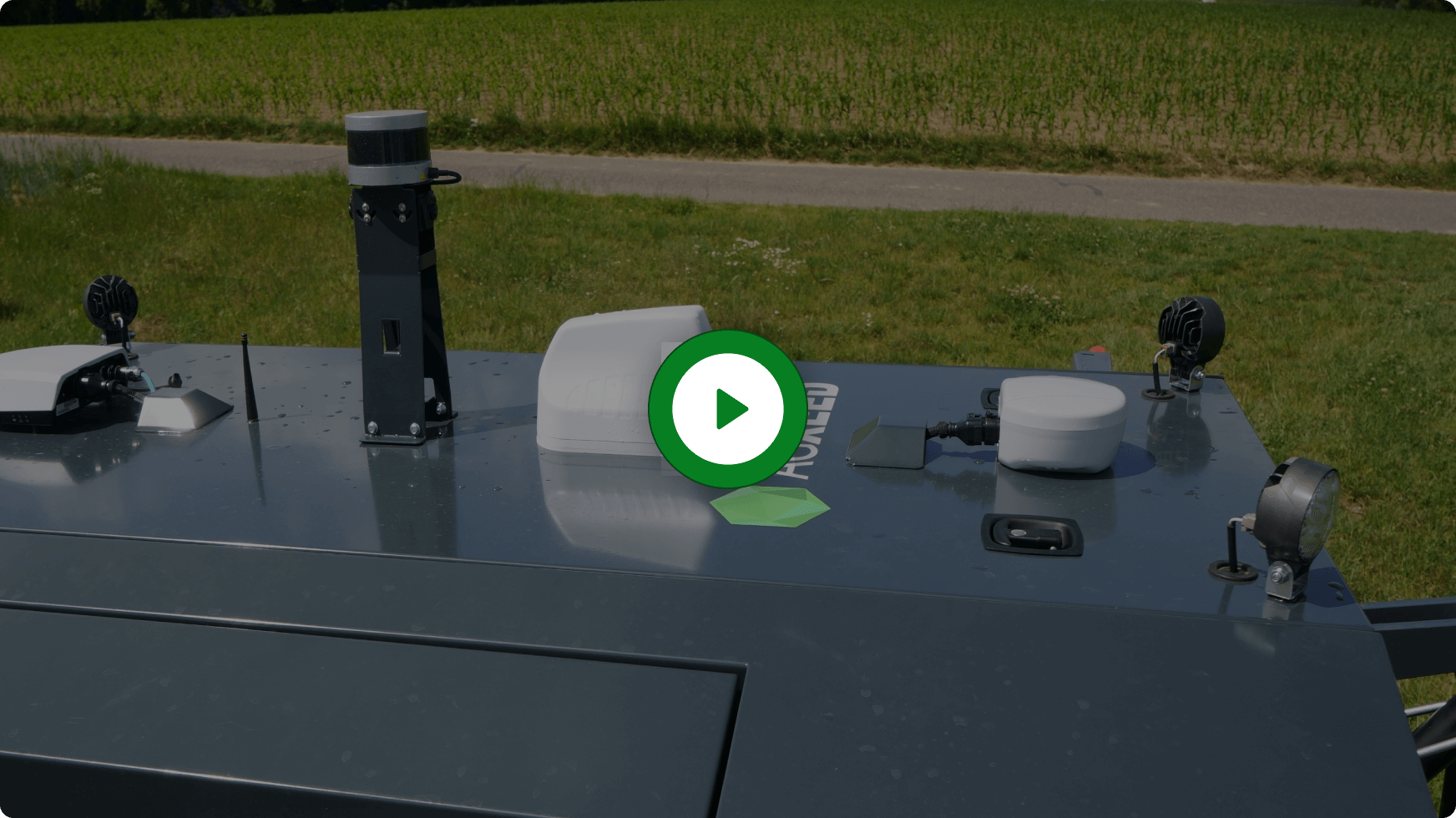

Obstacle detection system

- LIDAR sensor on the top of the machine

- Ultrasonic sensors integrated into the safety bumper

- Radar sensors integrated into the safety bumper

- Contact sensitive bumper integrated into the safety bumper

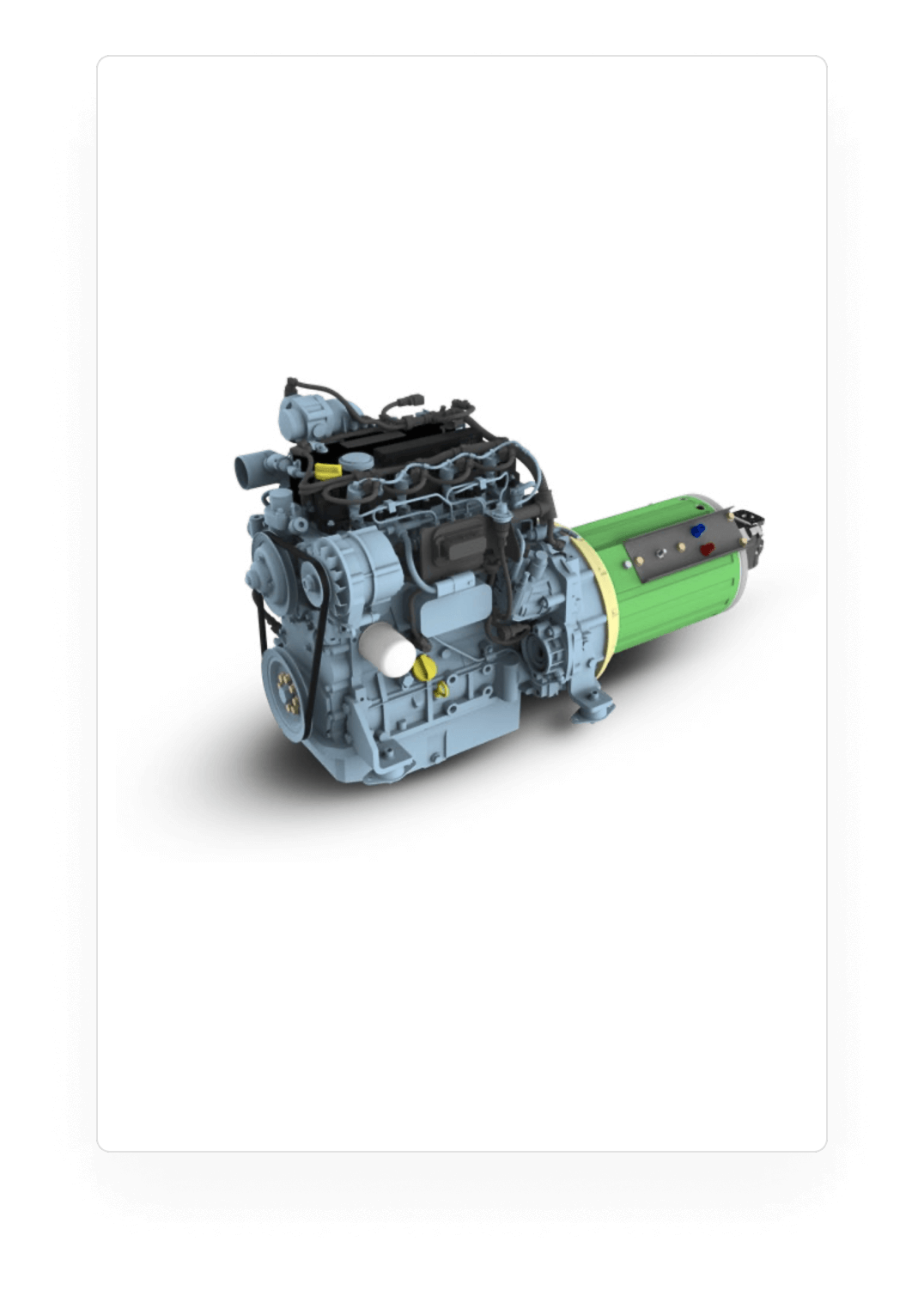

Drive train

Deutz Diesel Engine

4.1l 4-stroke Deutz Diesel Engine, stage 5 with 115kW / 156hp, max. torque of 610NmElectric driven PTO

Optional electric driven PTO (up to 100kW) +/- 1200 rpm completely variable in adjustment

Electric drive train

Electric drive train with a speed range from 0-13.5 km/hHighVoltage connectors

Optional HighVoltage connectors (up to 100kW and 700V)Diesel tank

350l diesel tank, 30l AdBlue tank

Hydraulics

Hydraulic pump

85l/min at 210bar hydraulic pumpRear linkage

Three-point rear linkage cat 3

8t maximum lift capacity at hooks

Spool valves

Up to 4 double-acting proportional spool valvesFront linkage

Three-point front linkage cat 2 (hooks cat 3)

3t maximum lift capacity at hooks

Load sensing

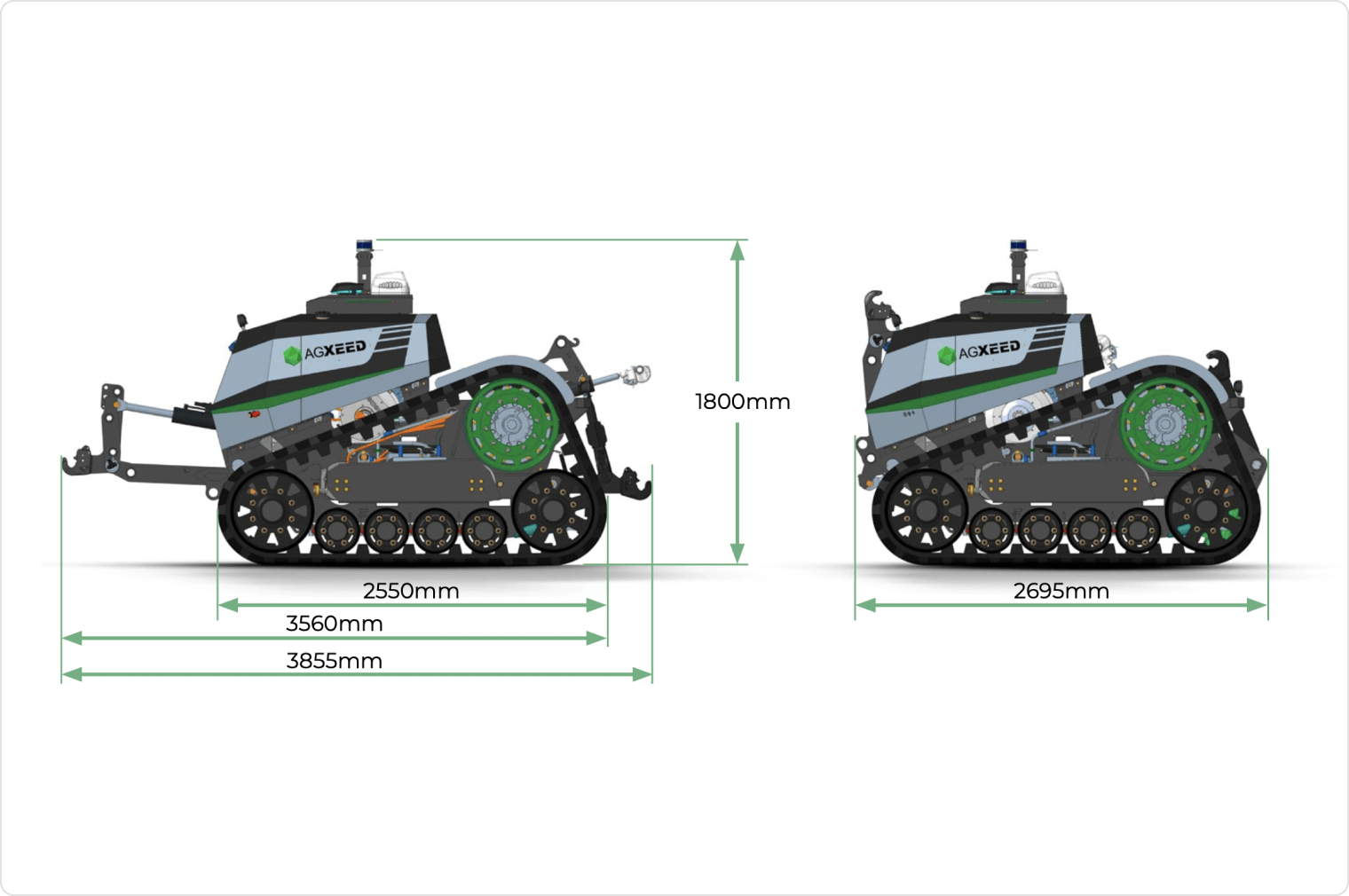

Optional Load SensingMachine dimensions

- Minimal length: 2695mm

- Height: 2000mm

- Total length with hitch at 90 degrees: 3600mm

- Empty weight: 7,8t

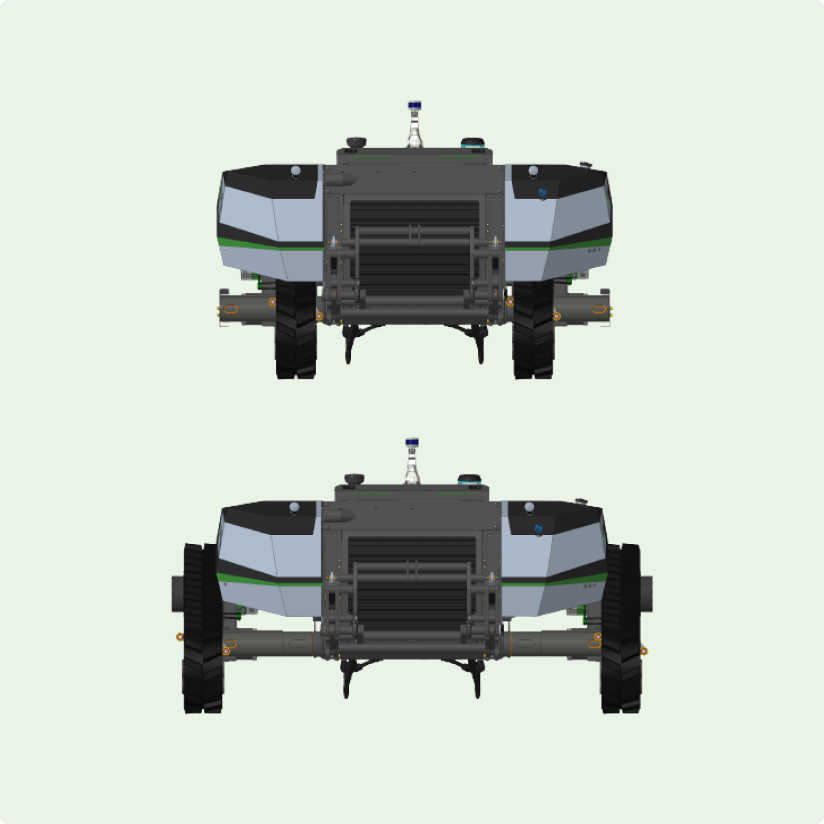

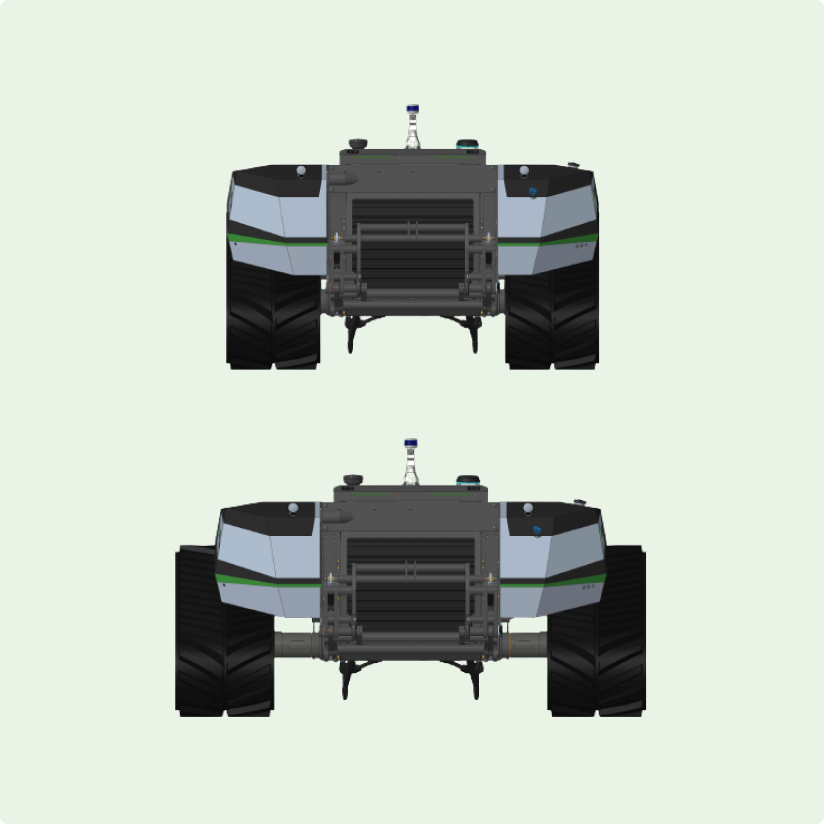

Track configuration

Variable track width adjustment

between 1900 and 3175mm or 2250 – 3075mm (range depending on the type of chassis and size of tracks)

Tracks from 300mm – 910mm width

Crop clearance 42cm

Track type

300 mmTrack width

1900 – 3175 mm

Transport width

3000 – 3500 mm

Track type

400 mmTrack width

1900 – 3175 mm

Transport width

3000 – 3600 mm

Track type

610 mmTrack width

2250 – 3075 mm

Transport width

3000 – 3460 mm

Track type

760 mmTrack width

2250 – 3075 mm

Transport width

3000 – 3610 mm

Track type

910 mmTrack width

2250 – 3075 mm

Transport width

3150 – 3460 mm

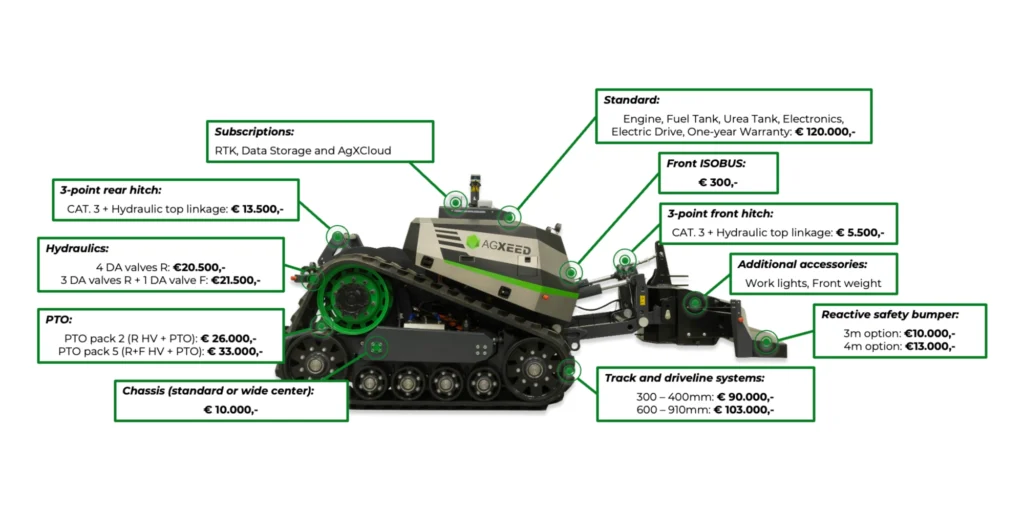

*Without dealer services, transport or customs fees, the suggested end customer price for AgBot 5.115T2 depending on the specification (see above)

Communication and positioning

- Communications module for bidirectional data transfer and RTK correction

- RTK GNSS for precise guidance and safe positioning: +/- 2,5cm

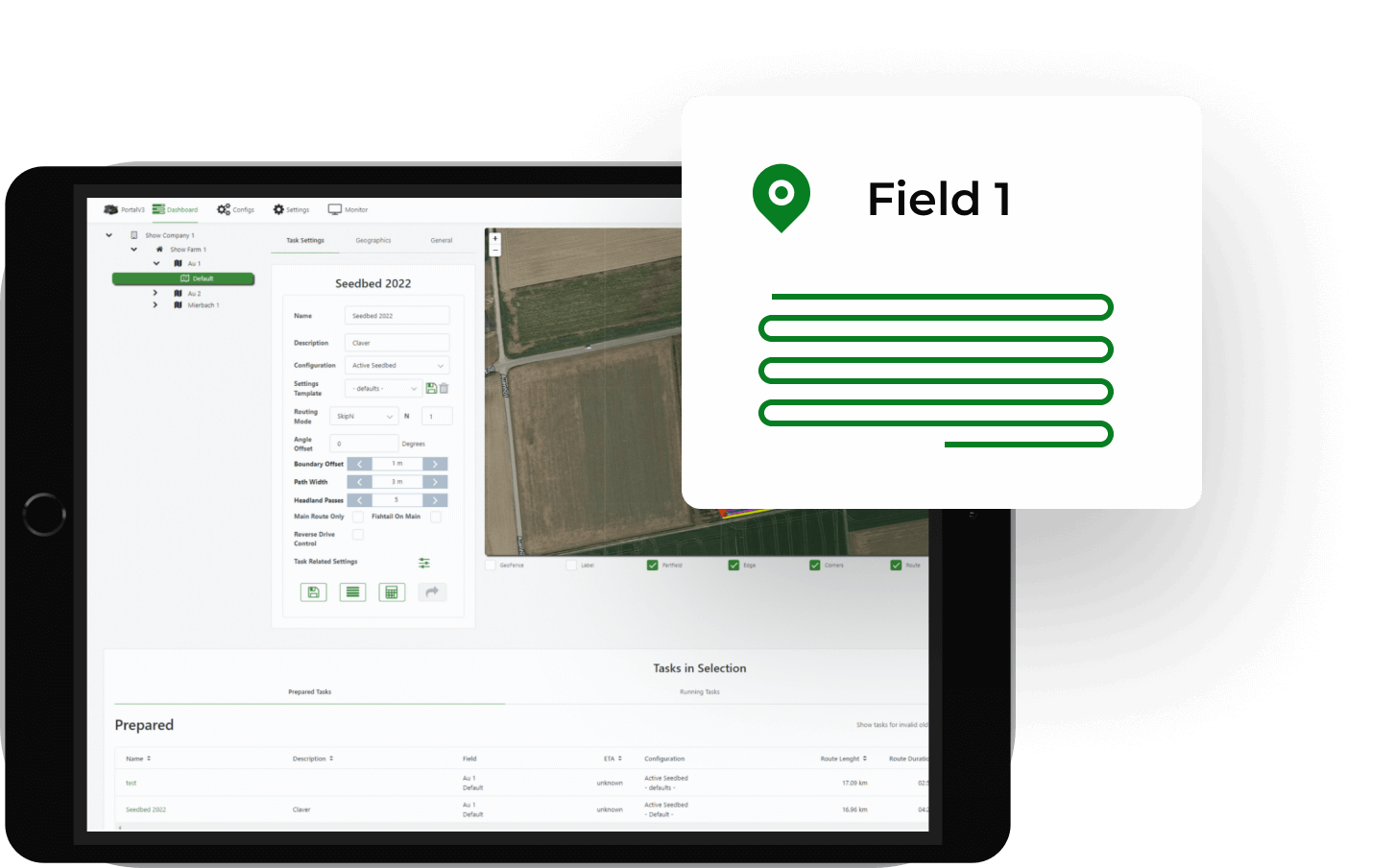

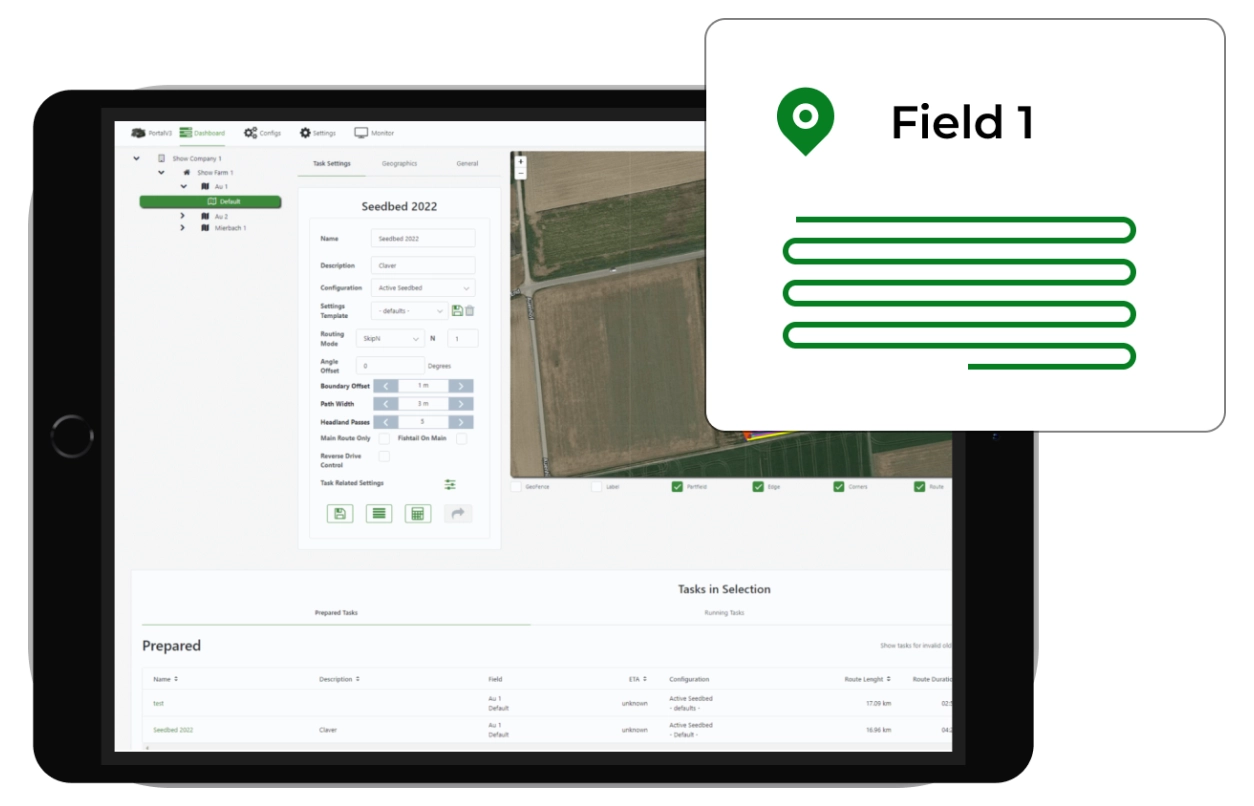

Farming starts here: Your AgXeed Portal

Manage, set up, control, and gather data received by AgBots in one intuitive application from anywhere.

“We didn’t expect the AgBot to be so easy to maintain: fill up, clean up the air-filter, oil once a week and off we go.”

Everyday tasks handled with ease

Soil preparation

- Implement: 3m front knife roller and 3m 3 row cultivator

- Speed: up to 10 km/h

- Depth: 15cm

- Soil: Sandy clay

- Topography: flat

- xx

Seedbed preparation

- Implement: 4m spring tine cultivator

- Speed: 11 km/h

- Soil: clay, limestones

- Topography: rolling slopes

- xx

- xx

- xx

Seeding

- Implement: 3m front tender packer and 3m rotary harrow with corn precision drill

- Speed: up to 8-12 km/h

- Soil: Sandy clay – humorous clay

- Topography: flat – light slopes

Other AgBots

AgBot 2.055W4

- Your versatile machine for light soil applications & maintenance

- Various adjustable wheel configurations and track widths

- Reach high capacity through continuity

AgBot 2.055W3

- Designed for smart applications in orchards and beyond

- 3-wheel design for even and soil preserving rollover

- Enables continuous working for maximum capacity

Farmers frequently ask

Please check out our distribution & service locator. Our partners are happy to organize a demo or visit to one of our current customers.

Our distribution partners will first survey your field by hand of GNSS technology. Afterwards they will upload the geofences into you personal AgXeed portal account. Once you log into the portal, your AgBots are already in there. To complete the story, our distribution partners will also digitize your implements, which will then be virtually connected to your AgBots in the portal. Now you are ready to set up your first tasks.

Select a field, choose one of your AgBot-Implement combinations and define your desired process parameters like working speed, working depth or hydraulic control valve settings. Afterwards you choose your desired reference A-B line and then the portal takes over and creates automatically the whole routing and task.